Manufacturing requirements for measurement range from presence verification to checking high-precision dimensional accuracy and geometrical tolerances. Attention to the inspection environment and image quality is as important as the vision algorithms themselves. DALSA sub-pixel measurement tools, combined with the right optics and stable lighting, provide the precision and repeatability to ensure manufacturing accuracy.

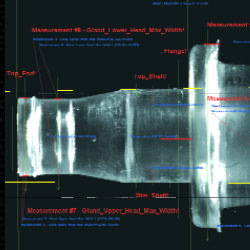

Strict tolerances on medical instruments

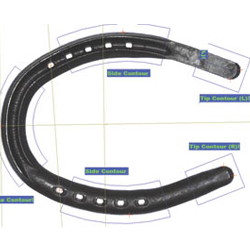

Horseshoe inspection -- line scan image

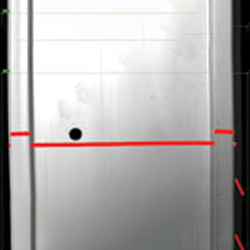

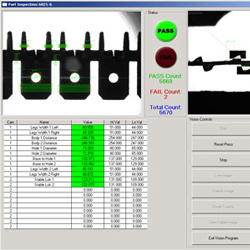

Electrical connector

dimensions

3D profile measurement

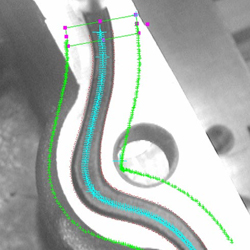

Bead inspection on automotive components

Metal connector inspection

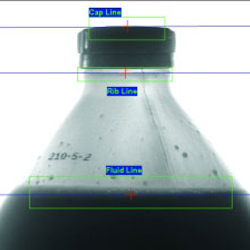

Fill level measurement