Sherlock® is an industry-leading no-code machine vision software development environment that provides a rich suite of proven tools and capabilities that have been deployed in thousands of installations worldwide. Sherlock is recognized throughout the machine vision industry for its flexibility to satisfy the full spectrum of vision inspection applications.

Sherlock 8 offers new and powerful development tools to expand applications beyond traditional image inspection. Sherlock supports a wide variety of area scan, line scan, and infrared cameras, and with added support for AI model inference and 3D measurements, it is possible to build more comprehensive inspection applications.

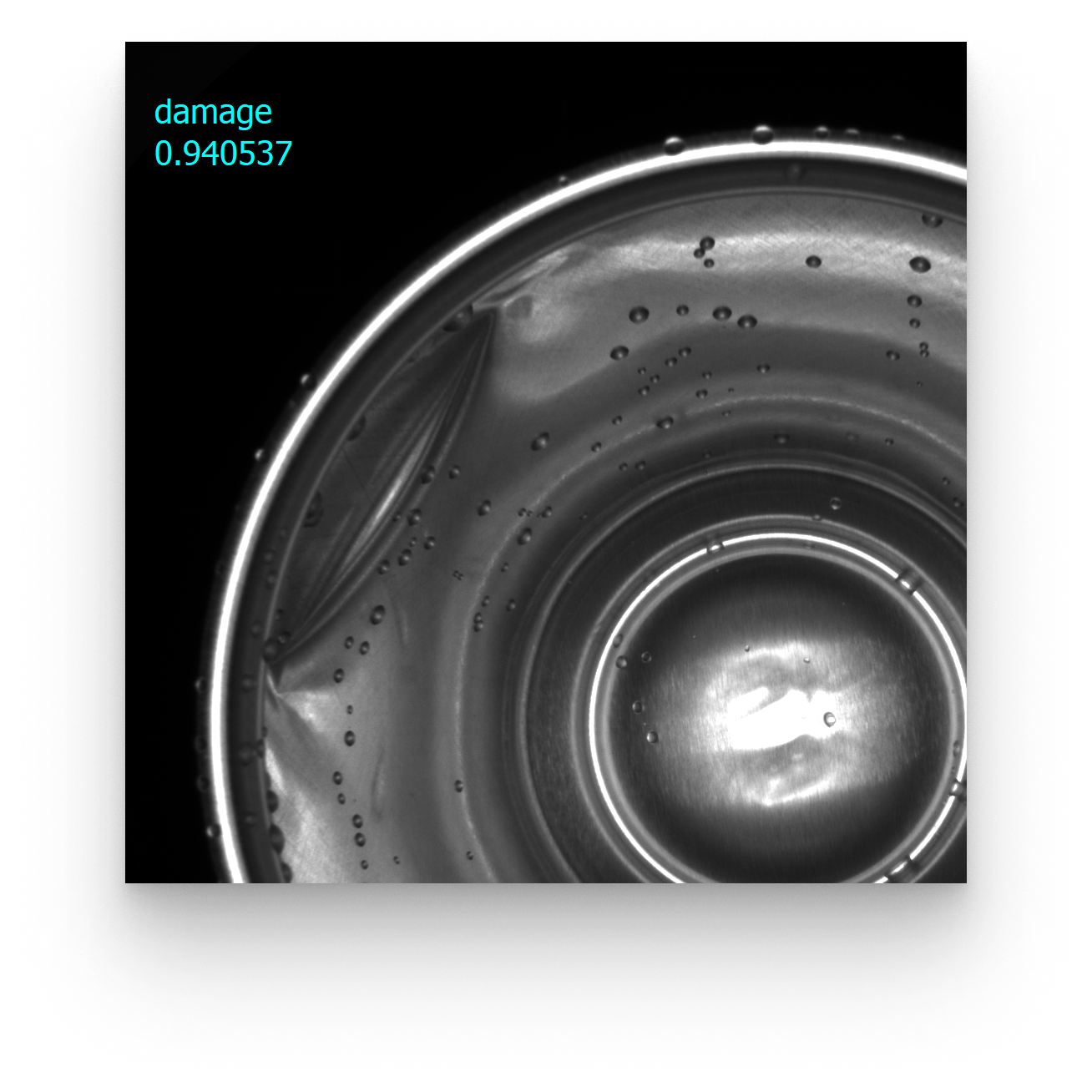

Build AI-Enabled vision systems with rapid, no-code development and deployment using Sherlock 8 and Astrocyte.

Sherlock is designed to work with Teledyne DALSA’s Z-Trak 3D laser profilers. Sherlock 3D Tools are a powerful and flexible package with strong graphical tools allowing for the easy integration of 3D part measurements into industrial applications.

Sherlock contains a wide range of computer vision algorithms designed and packaged for ease-of-use with graphical controls for development and fine-tuning.

Preprocessors

Extensive set of image conditioning functions that can be applied to ROIs prior to analysis.

Positioning Tools

Advance pattern-finding tools for object location and alignment.

Measurement Tools

Precise tools for locating edges and computing the dimensions on a variety of parts and shapes.

Analysis Tools

Tools for finding and counting edges, extracting and analyzing features, detecting contrast variation, and performing statistical analysis.

Calibration Tools

Correct for linear, nonlinear, and perspective image distortion. Convert camera pixel to real-world coordinates.

Color Tools

Teach colors or measure RGB values for precise manufacturing and quality checks.

Barcode Tools

Read and verify 1D and 2D codes. Check for code grading and quality. Supports most common code formats.

OCR Tools

Read and identify printed, molded, or stamped text. Teach character sets or use pre-trained neural-net based OCR tool.

Script Tools

JavaScript-based scripting tool, complete with drag-and-drop instruction editing, allowing the development of custom formulas or inline and background operations.

Administration

Controls for protecting against unauthorized access, editing, and copying.

Computational Imaging

Sherlock supports the Shape from Shading feature which combines multi-directional lighting with computational imaging algorithms to accentuate surface features which would normally be difficult to image using regular lighting.

Create custom operator interfaces using Sherlock’s no-code, drag-and-drop GUIBuilder™ tool or use .NET API to create powerful user interfaces. .NET API supports C++, C#, and Visual Basic® in Microsoft® Visual Studio®.

Designed for automated 24/7 on-premises operation, Sherlock provides easy-to-use tools to setup, read, and write data to factory automation devices such as PLCs and industrial robots. Sherlock supports communication protocols such as Modbus, Ethernet/IP, Profinet, OPC UA, MQTT, Serial, and supports onboard discrete IO controls.

Combines multi-directional lighting with advanced software algorithms to eliminate surface background effects, such as noise or color, and produce an output image focused on the features most relevant to the inspection. This output image can then be inspected using standard Sherlock vision tools. Ideal for features that have 3D texture, such as embossed characters, and impressed or indented features such as stamped or engraved markings.

Extract raised characters from tire sidewall

| Original | Extracted |

Extract date and lot characters pressed in a barcode

| Original | Extracted |

Hand-counting piston rings as small as 0.29 - 0.79 mm in width and packaging them in various batch counts, was not only adding to labor costs, but also proving unreliable in the highly competitive automotive sector. A far more reliable answer came in the form of a custom machine vision solution using Teledyne DALSA's Sherlock software.

Read the full article >>

| Document | Type |

|---|---|

| Sherlock 7.3 User Manual | |

| Sherlock 8.10 User Manual |