Many printed products (currency, tickets, commercial publications, newspaper, pharmaceutical and food packaging, and more) require 100% print inspection (often in color) as part of their quality control process; many require this inspection multiple times during production.

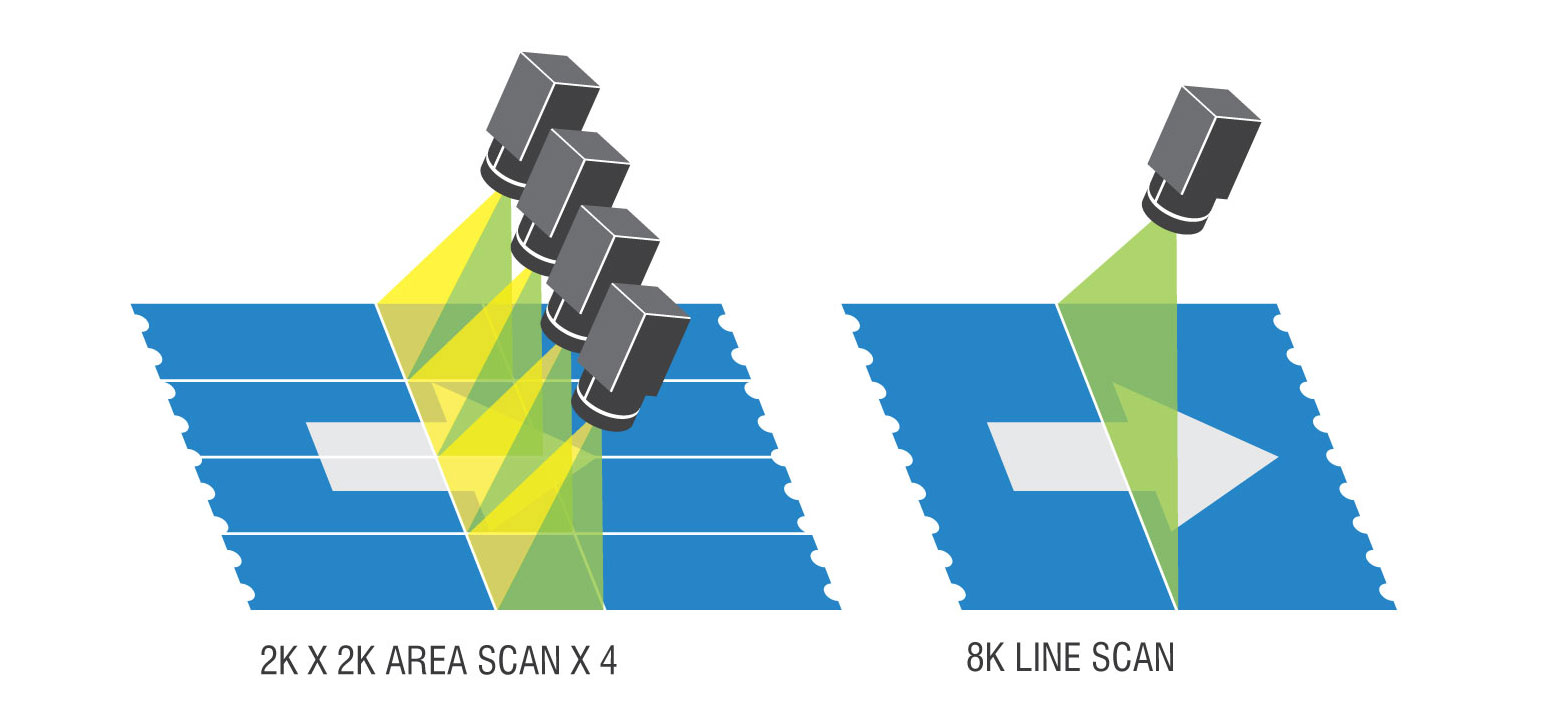

From paper to cardboard, plastic or metal, in continuous webs or sheets, print inspection applications are well suited to line scan systems. Line scanning offers unlimited pixels in the in the direction of a web's motion with zero smear even at high speeds, higher dynamic range, greater processing efficiency and much lower price/pixel.

High volume web inspection

Packaging inspection

Ticket inspection

Currency inspection

Line scan systems provide higher resolution with fewer cameras and inspect 100% of a moving surface without smear or the need to process frame overlaps.

Could your manufacturing process benefit from vision tasks like these?