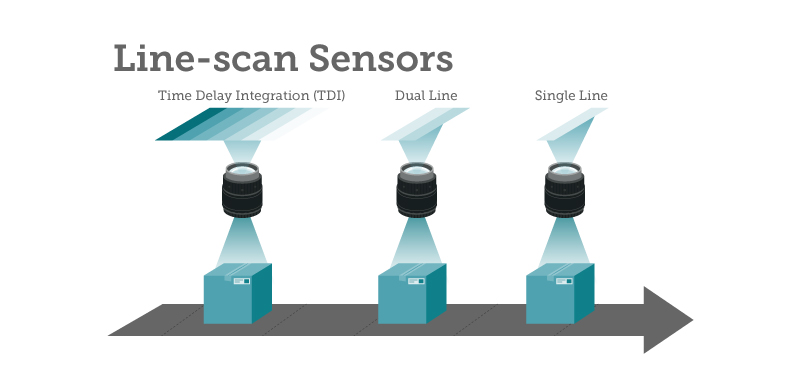

Teledyne DALSA's high sensitivity line scan products use TDI (time delay and integration) technology. TDI is a method of line scanning which provides dramatically increased responsivity compared to other video scanning methods. It permits much greater scanning speeds in low light, or allows reduced lighting levels (and costs) at conventional speeds. From wafer, PCB, and LCD panel inspection to high-end document scanning, Teledyne DALSA's advanced, high sensitivity line scan delivers an unmatched mix of sensitivity and speed.

TDI is based on the concept of accumulating multiple exposures of the same (moving) object, effectively increasing the integration time available to collect incident light. The object motion must be synchronized with the exposures to ensure a crisp image.

For more information, contact sales